DATA LOGGING

Standard Integrator

According to the classic method of data logging, the PM current is integrated for a predetermined period of time with the help of a capacitor. Several sparking events are integrated during this time and then put out as a voltage that is proportional to the light intensity and thus to the concentration of the element in the analyte.

It is practically impossible for a spark spectrometer to do without a so-called internal standard that eliminates the noise produced by the spark source. One or several emission lines of the matrix element serve as the internal standard or reference channel. As the internal standard has to satisfy high demands, the analysis and reference channels must be subject to identical changes (homologous pairs of lines).

GISS Integrator

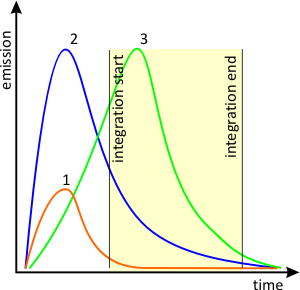

The spark plasma is characterised by high excitation temperatures of 10,000 K and more, which lead to the excitation and emission of numerous atomic and ionic lines. However, this also often means that not only the desired element line is emitted, but also interfering lines or a high level of continuous background radiation. The excitation of such interfering emissions is dependent on the plasma conditions. If one therefore detects the desired analysis signal in only one specific time window of the spark discharge, many perturbations can be avoided. Typically, the emission of ionic lines occurs earlier than the emission of atomic lines at low excitation energy. With the help of this time-resolved spectroscopy, many atomic lines can therefore be better detected during the “afterglow” of the spark plasma, especially as the spectral background will also have disappeared at this point. This method must be able to generate the right time window for each emission channel (gated integration).

The spark plasma is characterised by high excitation temperatures of 10,000 K and more, which lead to the excitation and emission of numerous atomic and ionic lines. However, this also often means that not only the desired element line is emitted, but also interfering lines or a high level of continuous background radiation. The excitation of such interfering emissions is dependent on the plasma conditions. If one therefore detects the desired analysis signal in only one specific time window of the spark discharge, many perturbations can be avoided. Typically, the emission of ionic lines occurs earlier than the emission of atomic lines at low excitation energy. With the help of this time-resolved spectroscopy, many atomic lines can therefore be better detected during the “afterglow” of the spark plasma, especially as the spectral background will also have disappeared at this point. This method must be able to generate the right time window for each emission channel (gated integration).

Apart from the integration of the analysis channel, the intensity distribution of the individual sparks permits conclusions to be drawn about the composition of the sample. For instance, when analysing an iron sample, a single spark can hit an inclusion and can be recognised by the higher signal given off by the inclusion elements. Single spark analysis permits assessment of the sample composition. Apart from detecting inclusions, the statistical data of the single spark analysis can be used to improve analytic precision.

Sensor Boards

In case solid-state sensor lines are used, their control and evaluation of measurement signals is more complex than a PMTintegrator. Each one needs precise timing schemes to read-out the pixels. OBLF uses multiline sensors. Therefore initially a vertical clock is required to transfer the charge of the photosensitive pixels in a read-out register. Thereafter, theread-out register is clocked out in sequence with a few MHzand digitized using a 16 bit AD converter. Via a bus system, a central controller receives the data of the entire emission spectrum.

In case solid-state sensor lines are used, their control and evaluation of measurement signals is more complex than a PMTintegrator. Each one needs precise timing schemes to read-out the pixels. OBLF uses multiline sensors. Therefore initially a vertical clock is required to transfer the charge of the photosensitive pixels in a read-out register. Thereafter, theread-out register is clocked out in sequence with a few MHzand digitized using a 16 bit AD converter. Via a bus system, a central controller receives the data of the entire emission spectrum.

Controller Unit

Integrator modules, sensor boards are addressed with a central controller which is also responsible for the acquisition of optics temperature and pressure. The electronics of the measurement system is located together with the optical system in the vacuum vessel. Critical readout circuits are also temperature stabilized and on the other hand, the required connections can be minimized in the vacuum flange.

.jpg)